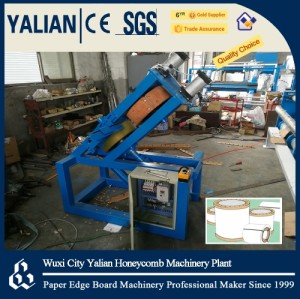

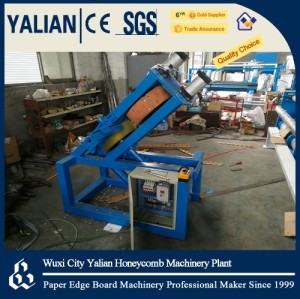

paper edge corner machine

Review

Description

This two function paper edge corner machine adopts Servo System; all operation actions are controlled by man-computer interface touch screen, frequency transformer control, and air cylinder cutting to make sure the paper edge cornersize accuracy. Adopt 8 group air cylinder pressure control sync pressing roller, making sure rotational speed uniform, pressure uniform, efficiently avoid surface paper wrinkle & broken. It is easy to change production from edge corner to flat board, no need to make operation to pressing roll. Machine video: https://youtu.be/i2u4WkRc5QA. Flat type machine video: https://youtu.be/O44Wl49x39g

Model | SKHJA |

specification | V-type:25-100mm, equal or unequal sides; flat board:50-200mm |

Edge corner thickness | 2-8mm |

Production speed | 0-35m/min; for flat board 0-35m/min |

Cutting tolerance | ±1mm/M |

Cutting length | ≥250mm |

Max layers | 13layers |

Installed power | 10kw |

Cutting ways | Cylinder cutting( with hydraulic unit) |

Gluing way | Double or single side both available |

Required operators | 2 |

Machine Characteristics:

• This paper edge corner machine has low request to paper.(can use low gsm paper: surface paper: 120-250gsm)

• Many gluing ways combination, controllable heating system, glue well-distribute, binding even.

• Adopt 8 group air cylinder pressure control sync pressing roller, making sure rotational

speed uniform, pressure uniform, efficiently avoid surface paper wrinkle & broken.

• Adjustable paper feed construction, changing specification easy and quick.

• Imported Servo System with high cutting accuracy. Cut tidy and good looks, avoid flash.

• Man-computer interface cooperation easy & convenience, the whole paper edge corner machine just needs 2 workers to operation.