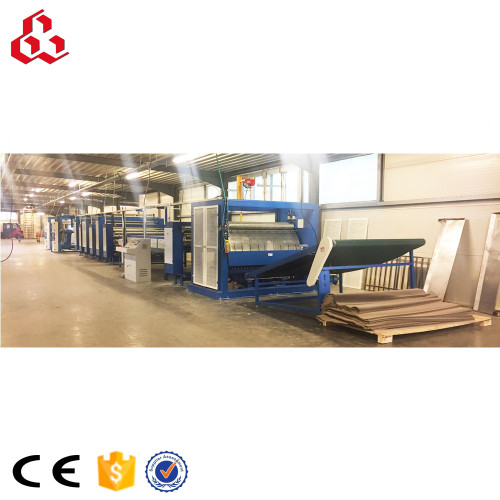

paper honeycomb core production line

Review

Description

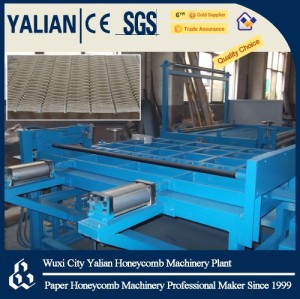

paper honeycomb core production line developed from the old lamination honeycomb core machine which is only can make honeycomb block and it is semi automatic, but nowadays this laminating paper honeycomb core production line is full automatically. It after paper laminated then cut into requested thickness and lamination again to consist of endless honeycomb core. During this proceed the paper wastage can be 0% at min. It is a real cost saving machine. And in the other hand, it has lower request to paper and glue, only need 2-3 workers to operate. It can help you minimize the production cost. Machine video: https://youtu.be/z_50M2y2Bnk

Model | 1600mm | 1800mm | 2000mm | ||

Core production type | Laminating paper honeycomb core production line | ||||

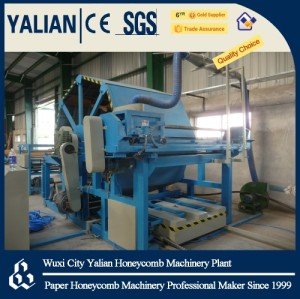

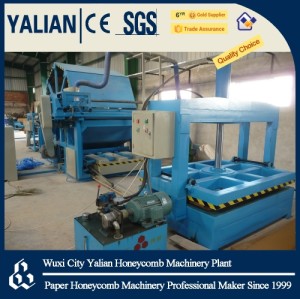

Configuration | Electric shaft less paper holder 3pcs( 6paper rolls available) Gluing Laminating Surface paper gluing High speed cutting Stacker | ||||

Max cutting speed | 350times/minutes | ||||

Max production | Around 3 tons | ||||

Max paper roll width | 1650mm | 1850mm | 2050mm | ||

Cell dimension | 6mm-100mm | ||||

Suitable paper gsm | 120-200gsm | ||||

Numbers of roll stands | 6 rolls | 6rolls | 6rolls | ||

Paper roll setting | Electric shaft less; Auto tension control; | ||||

Cutting control | Servo control | ||||

Total electric power | 40kw | 45kw | 50kw | ||

Machine dimension | 25MX4MX3.5M | ||||

Required operator | 2-3 operators | ||||

Main electric :

Touch screen & Frequency transformer & PLC using Delta (Taiwan brand)

Main electric parts using SIEMENS

Motor:SIEMENS

Bearing: SKF/NSK (Japan brand)

Cylinder:FESTO/SMC(Japan brand)

Service:

1. High engineers free assembling and training for max 15days. (Customer arranges accommodation and air tickets).

2. All parts one year maintenance (except easily damaged and man-made damager parts. In addition we will put some easily damaged parts in machine’s container according to our experience)

After one year, we will collect cost fee and will make follow-up service all life.