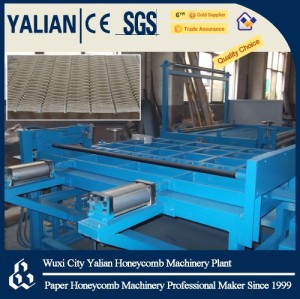

paper honeycomb core making machine

Review

Description

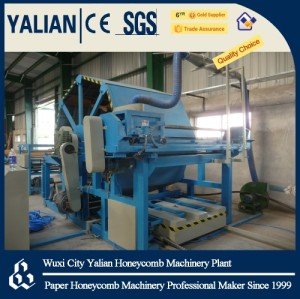

Octagonal drum semi-automatically paper honeycomb core making machine make honeycomb core block. Our factory has very mature technique in this honeycomb making machine making, the gluing line of this honeycomb core block in alignment, so the honeycomb core after expanding is very beautiful. Now many furniture factories use this machine to make paper honeycomb core stuffing in door. But generally this paper honeycomb core making machine must use together with honeycomb cutting machine, honeycomb connecting machine and honeycomb core expanding machine. Machine video: https://youtu.be/pEA0i1g-CxU.

Model | paper honeycomb core machine 1600mm |

Dimension | L*W*H :19m*2m*3.2m |

Power supply | 23.5kw |

Actual motor power consumption | 11kw |

Winding speed of drum | 0-60m/min |

Max paper core block width | 1650mm |

Capacity per shift | 6-8tons |

Core size available | 4-20mm |

Suitable glue | Starch glue or write emulsion glue |

configuration | Electric shaft less paper holder Glue device Octagonal rolling device 30mt pressing machine Paper core block cutting machine(optional) Core connecting & drying machine (notching is available) Computer control system |

Main electric :

Touch screen & Frequency transformer & PLC using Delta (Taiwan brand)

Main electric parts using SIEMENS

Motor:SIEMENS

Bearing: SKF/NSK (Japan brand)

Cylinder:FESTO/SMC(Japan brand)

Service:

1.High engineers free assembling and training for max 15days. (Customer arranges accommodation and air tickets).

2.All parts one year maintenance (except easily damaged and man-made damager parts. In addition we will put some easily damaged parts in machine’s container according to our experience)

3.After one year, we will collect cost fee and will make follow-up service all life.